The assembly has begun – 2016 Honda Africa Twin crash bars and skid plate

There’s been a tremendous amount of request for an update on the new Africa Twin CRF1000L manufacturing process. It’s right here. Only for you.

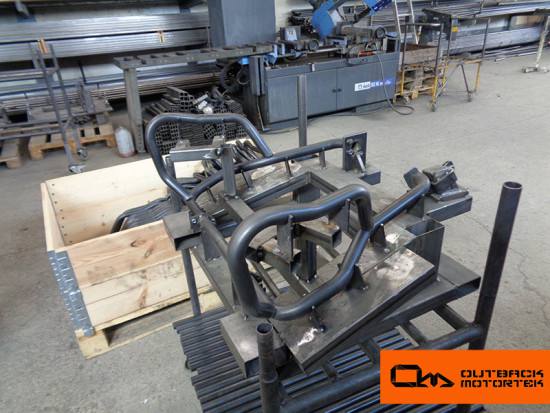

This is the first step I can introduce you to. We’ve got the crash bars laser cut components earlier this week and immediately begun working on CNC bending the tubes.

We didn’t just stop here: next step is welding. Definitely one of my favorite stages of the manufacturing.

And another exciting shot from a different angle.

The skid plates are ready for assembly, too. At least the first batch of 50 pieces.

It probably has not satisfied you hunger. More exciting stuff will be coming down the line and I’ll show you more of the behind the scene actions next week.

For now, we’re working seven days a week (yes, even Sunday!) to keep up with the demand and to meet the latest deadline of the end of June/first week of July.

Stay tuned.